Home

Welcome to Jon’s Machine Shop!

November 11, 2025: Not a very big update this time. There’s not much work being done in the shop right now. I’ve also not been very motivated to update this site. Too many other things competing for my attention.

I’ve added a toolpost grinder to the collection. So far, I’m not very impressed. The grinder works well enough, I just haven’t figured out how to use it. I’ve got two wheels for it. One is horribly unbalanced and the other breaks down faster than the material it’s grinding. I think I’ve got the balance problem sorted. Clearly, there is a learning curve with this machine.

I made a few parts for the Snapper mower. Most, if not all, could probably have been purchased. But where’s the fun in that?

I’ve added a few glass pieces to the suncatchers page. Not much glass work being done, though.

I’ve added a gallery for the Independence Day fireworks show this year. We actually had our show on the Fourth this year since it was also a Friday.

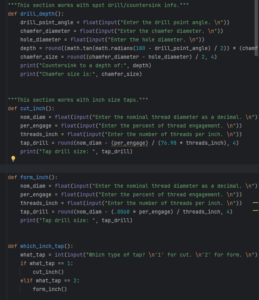

The biggest news, at least in my opinion, is that I’ve been learning Python. I have no reason to, it just seemed like a good challenge. I’ve added a page for that sort of work. It has its own tab in the menu. I’ve been working on a machinist calculator. It’s mostly just information for me. It’s also a good learning experience and fun to see it working. I keep adding more functionality to it, and will update the page as I go.

More to come.

As always, check back often for updates.